The European Institute of Innovation and Technology (EIT), an independent body of the European Union set up in 2008 to encourage innovation and entrepreneurship across Europe, held its expert forum on Sustainable Materials for Future Mobility, Electrification and Lightweight Design in Turin, Italy in early October.

The forum provided an opportunity to discuss European strategy around highlighting and securing raw material supply chains. A topic, which given recent geopolitical events in the world, is rapidly becoming of critical importance. The event also saw the EU Commission make announcements regarding sustainability and life-cycle analysis for battery raw materials and funding totalling €10Bn (US$1.09Bn) for research during the period 2021-2027.

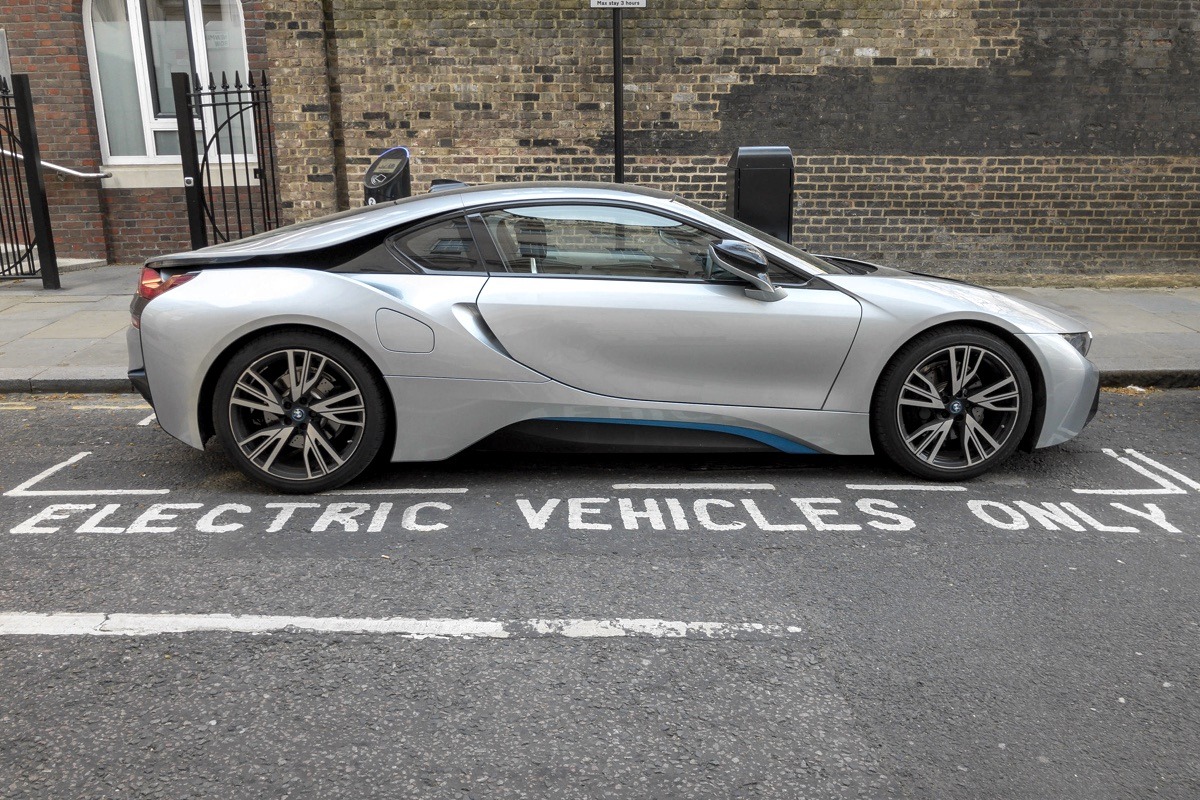

The analysts Roskill, who presented at the forum, stated that their forecast for major battery metals shows a strong and sustained growth in demand in the period leading up to 2030, with their analysis showing automotive applications to exceed 90% of global lithium-ion battery capacity demand by 2023. Augmenting this view is Fiat Chrysler Automobiles (FCA) who are forecasting between 50m-200m electric vehicles to be on the road in 2028, with that figure accelerating up to 900m units by 2040.

FCA discussed the broad range of battery metals they’ll require for their ambition in this area, for example, the move to NMC 811 cathodes in batteries, the reduction of rare earth elements in displays as the market moves to OLED displays, and the substitution of indium in touch screens with silver nano-wires and graphene nano-tube technologies.

Sustainability in the headlights

Whilst there is no doubt that the world will be crying out for more battery metals as electrification plays an increasingly larger part of our transportation mix, this in turn means the sustainability of raw materials will get picked put in the headlights, an issue highlighted by several presenters. Umicore stated that 30kt of cobalt was lost from the supply chain by batteries being disposed of rather than recycled. A metal which, as we reported last week, could be even harder to find in sufficient quantities following Glencore’s announcement to supply Shenzen-listed Gem Co with what could be up to 25% of their ‘sustainable’ forecasted cobalt hydroxide for the duration of the 2020-2024 contract.

Eramet is moving towards commissioning battery recycling in the EU with a pilot plant due to come online in 2020-2021.

The issue of alternate technologies to the lithium-ion batteries was flagged up, with SAFT and Solvay suggesting it will take at least another decade before solid state technologies will come to market. Recent news that Dyson is stopping development of its own electric vehicles, rumoured to be powered by a solid-state battery they were developing in-house following their 2015 acquisition of solid-state battery start-up Sakti3, may therefore come as less of a surprise.

To help stay up to date on the latest market trends of lithium-ion batteries, find out more about Roskill’s Lithium-Ion Batteries: Outlook to 2028.

For information on battery raw materials Roskill produce a range of reports covering lithium, cobalt, graphite and nickel markets.